Some Known Factual Statements About Sheroz Earthworks

Some Known Factual Statements About Sheroz Earthworks

Blog Article

Sheroz Earthworks Things To Know Before You Buy

Table of ContentsSheroz Earthworks Fundamentals ExplainedSome Ideas on Sheroz Earthworks You Should KnowThe Best Strategy To Use For Sheroz EarthworksRumored Buzz on Sheroz EarthworksRumored Buzz on Sheroz Earthworks

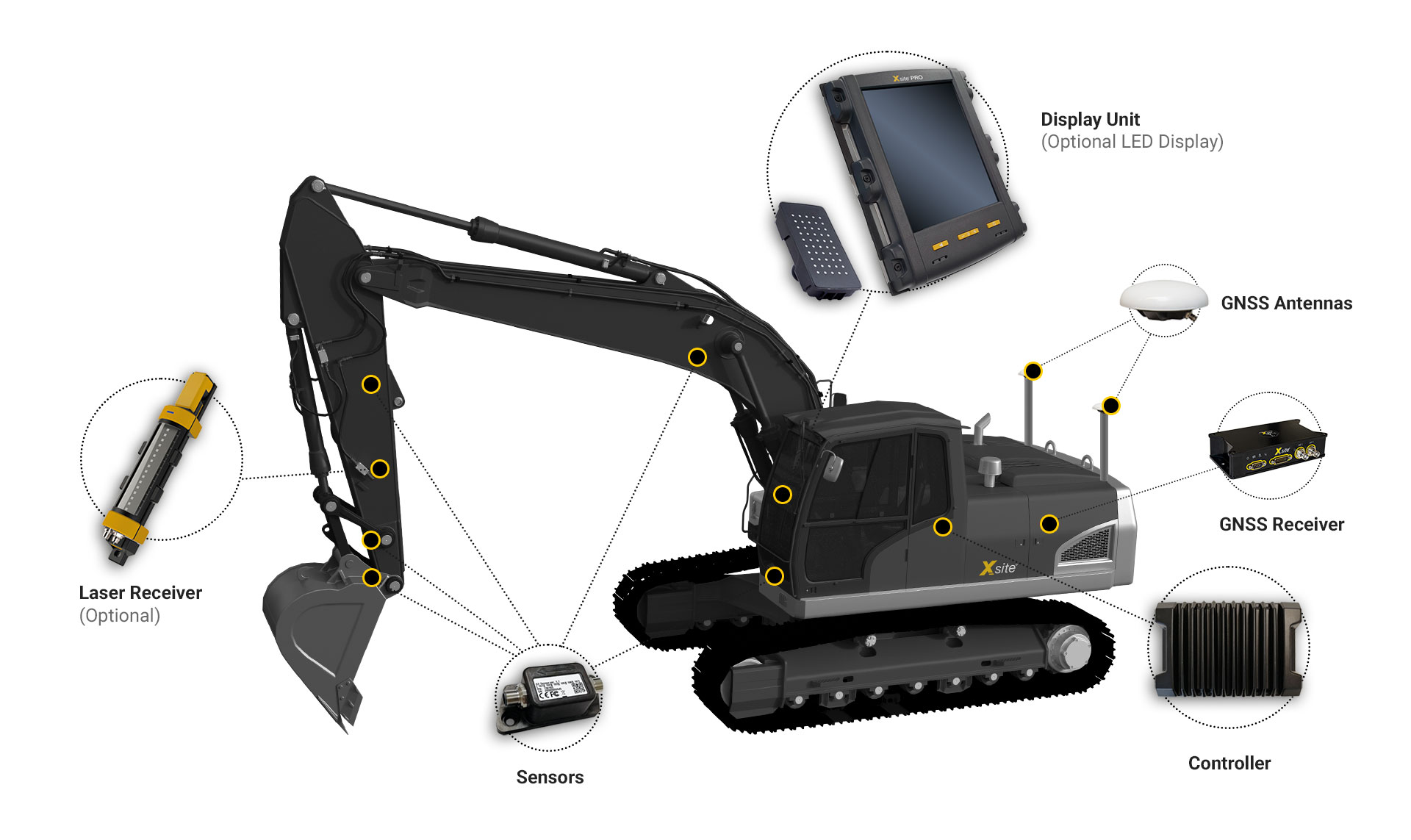

Instantly helped device GNSS technology is being integrated right into devices such as excavators, excavators, graders, pavers and farm equipment to enhance efficiency in the real-time operation of this equipment, and to supply situational understanding info to the tools driver. topcon. The fostering of GNSS-based device control is comparable in its influence to the earlier adoption of hydraulics innovation in equipment, which has actually had an extensive effect on performance and integrityThe accuracy attainable by GNSS-based services minimises the need to quit working while a survey team determines the grade. Supervisors and professionals have access to precise info regarding the task site, and the info can be checked out from another location. Individuals can print out status reports, save vital information and transfer documents to head workplace.

Device control systems are transforming the building and construction market by offering boosted accuracy, accuracy, and effectiveness. These systems make use of sophisticated modern technologies like GPS, lasers, and sensing units to direct and position heavy construction tools like excavators and excavators. It's vital to note that there are various kinds of machine control systems, and recognizing them is crucial for services looking to enhance their operations.

The Main Principles Of Sheroz Earthworks

These systems are fast and precise, making them perfect for grading projects and road building. GPS machine control systems utilize innovative satellite technology to guide building and construction tools. These systems can precisely map out building and construction sites, allowing the operator to see where they are, where they need to go, and chart their progress.

An Overall Terminal Maker Control System uses a remote-controlled tool called overall terminal to assist the device. Complete terminal systems are very precise and work well for building projects that include substantial vertical modifications, such as transporting planet to various levels. The total station gives off a laser, which is tracked by a prism affixed to the devices.

See This Report on Sheroz Earthworks

These systems are not as versatile as laser, GPS, or overall terminal systems as a result of the requirement for cable links, but they can be efficient in particular scenarios, like passage excavation, where line-of-sight guidance is more effective due to the low light conditions. Ultrasonic machine control systems utilize high-frequency sound waves to assist building tools.

Hydraulic device control systems make use of hydraulic pressure to manage the stress of building and construction devices, like excavators, excavators, and others. These systems are extremely exact and great for applications that need high precision - https://www.wattpad.com/user/sherozau. Optical machine control systems are similar to laser-based systems, yet they make use of optical sensing units to assist the heavy tools

Building companies use them for grading and road building and construction. Device control systems are significantly transforming the construction industry by giving even more precision, accuracy, and efficiency than ever. These systems rely upon advanced innovations like lasers, GPS, sensing units, and software programs to produce real-time feedback to the drivers that enable them to obtain better precision and effectiveness.

At SITECH, we offer a variety of exceptional quality maker control systems that are developed to meet the unique demands of your organization. Contact us today. https://www.reddit.com/user/sherozau/ to get more information about just how our machine control systems from Trimble can reinvent your building and construction jobs!

Examine This Report about Sheroz Earthworks

When it was presented to the market, first of all on excavators, in 2013, and after that on excavators, in 2014, Komatsu's completely integrated smart equipment control (iMC) system took the building market by storm with distinct assist functions for the operator, which fed via to large performance, effectiveness and cost conserving gains for clients in their earthmoving procedures.

Currently, 10 years on, Komatsu are commemorating a years of intelligent maker control, with a worldwide populace of over 14,000 iMC furnished equipments, that have clocked up over 40 Million running hours of value for their proprietors and operators. Each of these makers has the visit iMC innovation built-in at Komatsu's manufacturing facilities, suggesting the integrity of the system is guaranteed by the exact same, exact quality assurance.

This constant growth also provided on the product side, with the intro of smart Maker Control 2.0 (iMC 2.0) and a broadened range of excavators and dozers in 2020 and 2021. The brand-new iMC 2.0 functions Supply even more aid for the operator, by controlling tilt bucket change to match quality on the excavator, or automating the dispersing of pre-defined layers of material by the dozer blade.

Getting My Sheroz Earthworks To Work

Komatsu's constant devotion to continually improving customer value is not just attained via equipment improvements yet additionally via substantial enhancements in software program abilities. Amongst these is the introduction of an automated data-capture attribute to their iMC innovation. No matter of the maker's model or age, all systems can currently autonomously collect area and altitude information from dozer tracks and container edges.

Report this page